Flow Meter

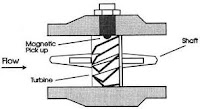

Flow Sensor

Ultrasonic flow meter

Ultrasonic Flow meter mempunyai dua jenis dari cara kerjanya yaitu doppler flow meter dan transit time flow meter sedangkan cara pemasangan ada secara inline dan clamp on. Sedangkan untuk tipe clamp on flow meter yang banyak sekali di minati adalah untuk karakteristik yang movable dimana flow meter ini bisa di bawah kemana mana. Dan karena kharakteristiknya yang cukup simple dan ringan flow meter ini sering disebut dengan istilah portable flow meter.

Ultrasonic flow meter cukup luas penggunaanya yaitu untuk fluid maupun untuk Gas. Ultrasonic flow meter yang digunakan untuk fluid mempunyai range aplikasi yang luas dimana bisa dipakai untuk matrial pipa dari bahan carbon steel, Stainless steel, PVC dan hingga pipa yang diberi lapisan seperti lapisan aspal, cement atau lainnya. Begitu juga untuk pemakaian pada temperature dan pressure yang tinggi, flow meter ultrasonic ini cenderung lebih stabil. Sedangkan untuk aplikasi pada bahan liquid yang mungkin corosive karena terlalu asam atau basa maupun untuk kwalitas liquid yang jelek karena kotor mengandung serat produksi seperti di tekstil atau di industri pulp ataupun banyak mengandung bahan solid maka bisa dikatakan ultrasonic flow meter ini mempunyai kecocokan dari segi akurasi dan ketahanan atau life time ultrasonic akan cukup lama karena tidak adana bahan yang tecontact langsung dengan liquid khususnya untuk jenis clamp on ultrasonic flow meter.